Why would a Gas Generator become the quiet hero behind my uptime strategy?

2025-11-21

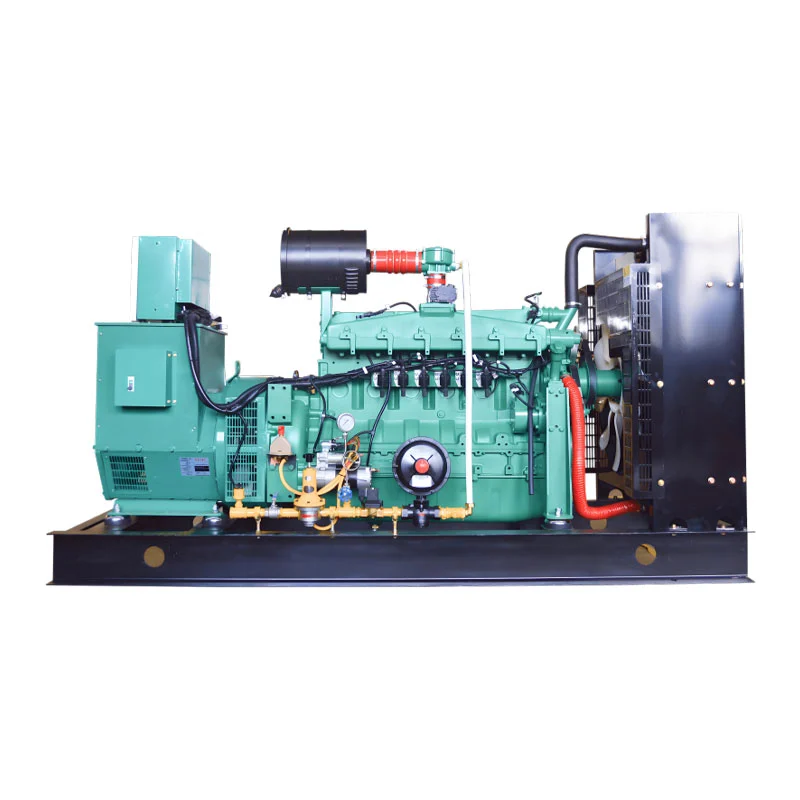

When outages hit, I do not want drama, I want power that behaves. Over the past few years I have helped facilities build resilient plans where reliability and operating cost actually make sense. In that journey, I kept returning to Kecheng, because the team understands how a modern Gas Generator fits into real projects. I will walk through the decisions I make in the field, the trade-offs I see every week, and how a thoughtfully specified Gas Generator solves problems.

What problems do I actually solve with a modern Gas Generator?

I use a Gas Generator when I need dependable backup or prime power that is cleaner, quieter, and easier to refuel than diesel. It stabilizes critical loads, keeps HVAC and servers online, and prevents production scrap when the grid blinks. It also pairs well with demand response and microgrids so I can monetize capacity instead of treating it like a sunk cost.

- Grid volatility becomes manageable because start times are fast and load acceptance is smooth

- Fuel logistics stay simple with piped natural gas or on-site LPG and biogas options

- Noise and emissions drop to neighborhood-friendly levels when enclosures and aftertreatment are chosen well

- Total cost moves down as maintenance intervals extend and fuel burn per kWh improves

How do I size a Gas Generator without overpaying?

I begin with a clean load list and separate inrush-heavy motors from sensitive electronics. I look at true peak demand, diversity, and the highest single step load. Then I check altitude and temperature because they de-rate real performance. With those facts, I select a Gas Generator that can accept the largest step while staying inside voltage and frequency limits, and I add a pragmatic margin rather than a guess.

- Measure starting currents and use soft starters or VFDs to tame inrush where it matters

- Plan for future growth by reserving space in the switchboard and slab, not by oversizing the machine today

- Confirm gas supply pressure and flow so the unit never starves during cold snaps

Which fuel and configuration make the most sense for my site?

I pick fuel based on availability, price stability, and sustainability goals. Natural gas is my default for urban sites. LPG works for remote locations. Biogas adds circular value on farms and plants. I also decide between open-set and containerized systems and whether I want a single unit or modular blocks that scale.

- Natural gas for steady supply and lower local emissions

- LPG where piping does not reach or as a dual-fuel buffer

- Biogas when waste streams already exist on site

- Modular blocks when I need N+1 redundancy without a single point of failure

What performance metrics do I watch if I want low total cost of ownership?

I track efficiency at realistic part loads, oil change intervals, spark plug life, and start reliability. I also monitor harmonic distortion, short-circuit performance, and the health of the automatic transfer switch. The right Gas Generator proves itself by running clean at 50 to 80 percent load most of the time and by starting on demand without fuss.

- Fuel consumption per kWh at 50, 75, and 100 percent loads

- Maintenance hours per year and consumables per cycle

- Time to rated voltage and frequency after start

- Remote monitoring uptime and alert accuracy

How does my selection compare across key criteria in real projects?

When I present options, I summarize the trade-offs so non-engineers can decide quickly. The table below mirrors how I explain choices on day one and shows where a Gas Generator gives me practical wins.

| Criterion | What it means | Typical range with a Gas Generator | Why it matters |

|---|---|---|---|

| Start time | Seconds from start signal to stable power | 10 to 30 seconds with ATS coordination | Protects servers, freezers, process lines from sag |

| Load acceptance | Largest step load without disturbing voltage and frequency | 40 to 70 percent of rated kW per step | Determines motor starts and elevator recovery after outage |

| Fuel logistics | How fuel reaches the engine during bad weather | Piped gas or on-site LPG with two-week autonomy | Removes diesel trucking risk and storage headaches |

| Acoustic profile | Noise outside the enclosure under load | 65 to 75 dB(A) at 7 m with proper enclosure | Keeps neighbors and staff comfortable |

| Service intervals | Hours between routine service tasks | 250 to 500 hours with modern oils and plugs | Cuts downtime and technician visits |

| Emissions | Local air impact and compliance margin | Lower NOx and particulates than similar diesel sets | Simplifies permitting and ESG reporting |

What installation and safety details do I lock down before commissioning?

I finalize foundation, ventilation, and exhaust routing early. I make sure gas trains include filtration, regulation, and shutoff with the right approvals. I confirm grounding, bonding, and clearances so service is safe and fast. I test the automatic transfer switch under real load and I document one-line diagrams so midnight callouts are calm.

- Concrete pad with vibration isolation and service access on all sides

- Intake and discharge sized for worst-case ambient and load

- Gas pressure regulation tuned to the engine specification

- Fire protection and gas detection integrated with site alarms

How do I keep uptime high when heat waves and storms hit?

I run monthly tests under meaningful load, not empty spins. I keep spares on site and I enable remote monitoring with alerts that actually reach the right person. A well-maintained Gas Generator rides through seasonal extremes because the team treats it like production equipment rather than a dusty insurance policy.

- Exercise under at least 30 percent load to prevent wet stacking

- Inspect belts, hoses, and coils before peak seasons

- Validate ATS logic after any switchboard work

- Review trend data and fix small anomalies early

Where do sustainability and emissions fit into my business case?

I reduce local pollutants and improve carbon intensity compared to many diesel fleets, and I unlock combined heat and power when waste heat is useful. That turns a backup asset into a productive asset. In several facilities, a Gas Generator plus CHP covered baseload while rooftop solar shaved peaks, all managed by a simple controller.

When should I choose a Gas Generator over a diesel set or a battery system?

- I choose a Gas Generator when I need long run times without fuel deliveries and when noise and local emissions matter

- I choose diesel when I must meet the fastest start and highest transient motor starts in remote sites without gas access

- I choose batteries for short, silent bridging and power quality, often alongside engine generation

What results do I normally see in the first ninety days?

- Reliable starts with documented test logs and clear point-of-contact roles

- Fuel costs that match the forecast because the load plan is realistic

- Staff confidence because procedures are simple and training is complete

- Clean reports for compliance and sustainability teams

Would you like a tailored proposal that fits your load and budget today?

If you want a calm, evidence-based path to resilient power, tell me about your site and I will help you map a plan that delivers results. Share your demand profile, preferred fuel, and timeline, and we will size a Gas Generator that works the first time. To start a quick conversation with Kecheng, please contact us with your questions and request a quote now. If you are ready, contact us today and let us turn downtime into a non-event.