What Makes Industrial Heat Pumps the Future of Efficient Heating and Cooling Systems?

2025-11-12

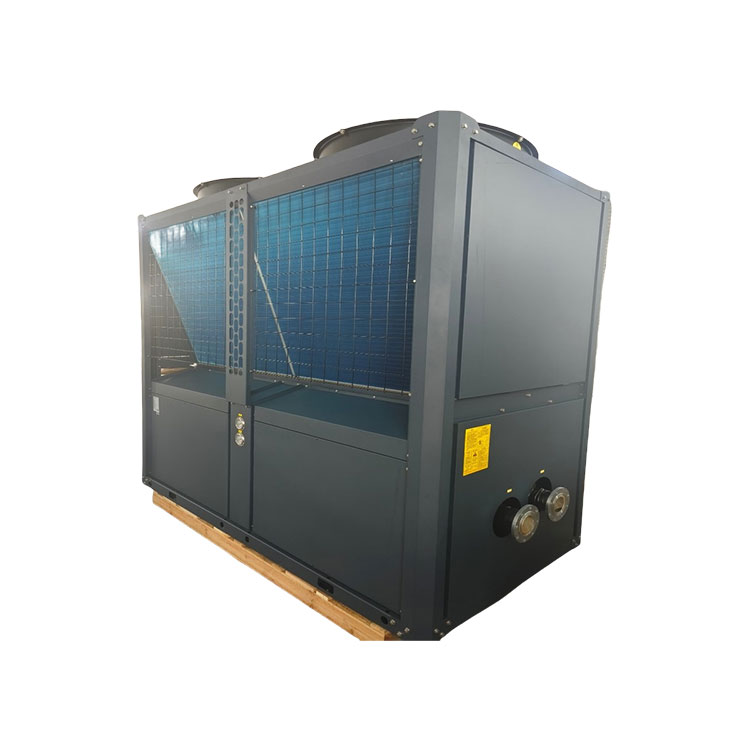

An industrial heat pump is a high-efficiency heating and cooling system that transfers thermal energy from one place to another using a refrigeration cycle. Unlike traditional boilers or chillers, which rely on direct fuel combustion or separate cooling systems, industrial heat pumps utilize electricity to move heat instead of generating it through burning fuel. This process makes them one of the most energy-efficient and eco-friendly options for industrial and commercial applications today.

Industrial heat pumps can extract heat from air, water, or ground sources and upgrade it to a higher temperature suitable for space heating, water heating, or industrial processes. These systems are used in manufacturing, food processing, chemical plants, and other industries that require both heating and cooling capabilities simultaneously.

The article explores the advantages, working principles, and future trends of industrial heat pumps, as well as why companies are increasingly choosing them as a core part of their energy transition strategy.

Key Product Parameters of an Industrial Heat Pump:

| Parameter | Description |

|---|---|

| Heating Capacity | 30 kW – 2000 kW (customizable based on application) |

| COP (Coefficient of Performance) | 3.5 – 6.0 depending on the operating environment |

| Temperature Range | -15°C to +90°C output temperature |

| Refrigerant Type | R134a, R410A, R1234ze, or eco-friendly low-GWP refrigerants |

| Compressor Type | Scroll or screw compressors for high efficiency |

| Power Supply | 380V/50Hz or 440V/60Hz (three-phase industrial standard) |

| Applications | Industrial drying, process heating, space heating, hot water production, waste heat recovery |

| Control System | PLC intelligent control with digital monitoring interface |

| Material | Stainless steel heat exchangers and corrosion-resistant components |

| Noise Level | <60 dB for most models, designed for low operational noise |

By understanding these specifications, it becomes clear that industrial heat pumps are engineered to deliver consistent performance and operational reliability, even in demanding industrial environments.

Why Are Industrial Heat Pumps the Preferred Choice for Modern Industry?

The growing demand for sustainable energy solutions has made industrial heat pumps an essential part of industrial transformation. They are not only more energy-efficient but also reduce carbon emissions and long-term operational costs. But what truly makes them a preferred choice in modern industry?

a. High Energy Efficiency and Cost Savings

Industrial heat pumps typically achieve energy savings of up to 50% compared to traditional heating systems. Their Coefficient of Performance (COP) indicates how efficiently they convert electrical energy into heat output. A COP value of 4 means the system provides four units of heat for every unit of electricity consumed. Over time, this efficiency translates into substantial cost reductions for large-scale operations.

b. Reduced Carbon Footprint

Since heat pumps transfer heat rather than generate it, they emit significantly less CO₂. When paired with renewable electricity sources, such as solar or wind, their environmental impact is nearly zero. This aligns perfectly with global carbon reduction targets and corporate sustainability initiatives.

c. Versatile Applications Across Industries

From food processing and textile drying to chemical production and wastewater treatment, industrial heat pumps can be adapted for various temperature ranges and heating demands. They can recover waste heat from manufacturing processes and reuse it, improving the overall energy balance within a facility.

d. Stable and Safe Operation

Compared with fossil fuel-based boilers, heat pumps eliminate combustion risks and minimize maintenance. The systems are equipped with advanced PLC control panels, temperature sensors, and safety protections to ensure stable and continuous operation with minimal human supervision.

e. Compatibility with Renewable Energy Systems

Industrial heat pumps integrate easily with renewable energy infrastructure. When powered by solar panels or wind turbines, they create a fully sustainable heating and cooling loop—offering a practical way to decarbonize energy-intensive industries.

f. Long-Term Investment Benefits

While the initial cost of installation may be higher than traditional systems, the operational savings, government incentives, and environmental benefits far outweigh the upfront expense. Many regions also provide tax reductions or green subsidies for companies investing in energy-efficient technologies.

How Are Industrial Heat Pumps Transforming the Future of Energy Systems?

The transition to clean energy and carbon neutrality is driving innovation in heating technologies. Industrial heat pumps are at the center of this revolution, offering a scalable solution for reducing energy waste and improving efficiency.

a. Integration with Smart Manufacturing Systems

In the era of Industry 4.0, modern industrial heat pumps are increasingly integrated with smart monitoring systems that allow real-time data collection, performance tracking, and predictive maintenance. This ensures maximum efficiency while minimizing downtime.

b. Waste Heat Recovery for Sustainability

One of the key trends in industrial heating technology is waste heat recovery. Industrial processes often release significant amounts of heat that would otherwise go unused. Heat pumps can capture and repurpose this energy, converting it into useful heating or hot water, thus lowering both energy costs and emissions.

c. Use of Eco-Friendly Refrigerants

New refrigerants like R1234ze and CO₂ (R744) are replacing older, high-GWP gases, making heat pumps more environmentally responsible. Manufacturers are designing systems that meet or exceed international energy and environmental standards such as ISO 14001 and EU Ecodesign requirements.

d. Expanding Market Demand and Government Support

Countries around the world are promoting electrification and decarbonization through incentives and policy measures. The industrial heat pump market is projected to grow rapidly as factories and processing plants replace traditional fossil fuel-based systems. By 2030, the industrial heat pump sector is expected to become one of the most vital contributors to global carbon reduction efforts.

e. Hybrid Heating Systems and Advanced Controls

Future industrial heat pumps will feature hybrid configurations, combining multiple energy sources (e.g., electric heat pumps with gas backup systems) to ensure reliability and flexibility in various climates. AI-based control algorithms and Internet of Things (IoT) connectivity will further enhance their efficiency and adaptability.

f. Customization and Modular Design Trends

Manufacturers are focusing on modular systems that can be easily expanded or adapted to different facility sizes and requirements. Modular industrial heat pumps can be installed quickly, maintained easily, and scaled up as industrial demands increase.

Common Questions About Industrial Heat Pumps

Q1: What maintenance is required for an industrial heat pump system?

A1: Industrial heat pumps are designed for long-term, low-maintenance operation. Routine maintenance involves checking refrigerant levels, cleaning heat exchangers, inspecting electrical connections, and verifying the compressor’s oil condition. The control system continuously monitors operating data, allowing technicians to identify and address potential issues before they affect performance. Properly maintained systems can last more than 20 years with minimal efficiency loss.

Q2: How can industrial heat pumps be optimized for maximum efficiency?

A2: Efficiency can be optimized by ensuring proper system sizing, maintaining clean heat exchange surfaces, and monitoring inlet and outlet temperature differentials. Using advanced variable-speed compressors and integrating the system with a smart control platform further improves performance. Heat recovery from waste streams and using renewable electricity sources also contribute to higher energy savings.

Conclusion: How MEIBIXI Leads the Innovation in Industrial Heat Pump Solutions

Industrial heat pumps represent a technological leap in sustainable energy management, delivering efficiency, reliability, and environmental responsibility across industries. As businesses strive to reduce operational costs and meet global carbon goals, these systems offer a long-term, scalable solution to modern energy challenges.

MEIBIXI, as a professional manufacturer and supplier of industrial heat pump systems, focuses on delivering customized solutions with high energy efficiency and advanced control technology. With decades of experience and continuous innovation, MEIBIXI’s products serve a wide range of industrial applications—from manufacturing and processing to environmental engineering—helping enterprises transition toward a low-carbon future.

For more information about industrial heat pump systems, product specifications, or customized solutions, please Contact Us to discuss your project needs and learn how MEIBIXI can support your energy transformation goals.