How Does PV Solar Cable Enhance System Efficiency and Long-Term Power Reliability?

2025-12-09

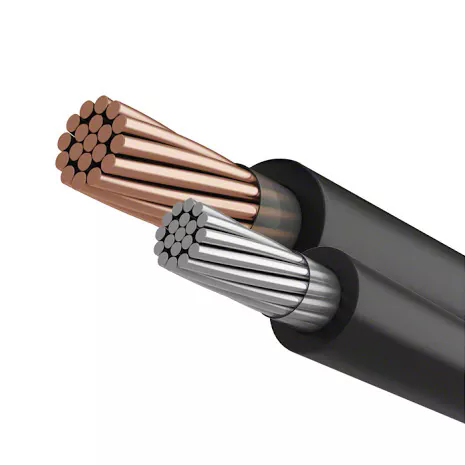

PV solar cable is one of the core transmission components in any photovoltaic system, responsible for safely carrying DC power from solar panels to inverters and distribution equipment. Its electrical conductivity, insulation quality, UV resistance, and temperature tolerance directly influence the efficiency, durability, and stability of a solar array.

Product Overview and Technical Parameters: How Do PV Solar Cable Specifications Influence System Output?

High-quality PV solar cable is designed with tinned copper conductors, XLPO or XLPE insulation, and double-layer sheathing that ensures extreme weather endurance. Its construction allows efficient power transfer while reducing energy loss—critical for both residential and large-scale solar plants.

Below is a detailed parameter overview commonly used in professional photovoltaic installations:

| Parameter | Specification |

|---|---|

| Conductor Material | Tinned Copper Class 5 (Flexible Stranded) |

| Cross-Section Sizes | 2.5mm² / 4mm² / 6mm² / 10mm² / 16mm² |

| Insulation Material | XLPO / XLPE UV-Resistant |

| Rated Voltage | 600/1000V AC, 1000/1800V DC |

| Temperature Range | –40°C to +120°C |

| Test Voltage | 6.5 kV, 50 Hz, 5 min |

| Flame Retardant | IEC 60332-1 / EN 50618 |

| UV / Ozone Resistant | Yes |

| Weather Resistance | Excellent for outdoor continuous use |

| Standards | IEC 62930, TUV, UL4703 (as required) |

| Expected Service Life | >25 years under normal outdoor conditions |

These parameters establish the mechanical and electrical durability required to operate within demanding solar PV environments—ensuring safe and stable power delivery for decades.

Advantages and Functional Strengths: How Does PV Solar Cable Improve Solar Installations?

A. High Conductivity and Lower Line Loss

Tinned copper conductors improve current flow while maintaining low resistance. This directly increases system efficiency, especially in large solar farms where cable lengths are significant.

B. Superior Weather and UV Resistance

Outdoor solar facilities require cables that can withstand extreme heat, cold, moisture, and long-term UV radiation. XLPO and XLPE insulation prevents cracking, deformation, and electrical leakage.

C. Enhanced Safety Performance

With high flame retardancy, double insulation layers, and anti-aging properties, PV solar cable reduces the risk of overheating, short-circuits, and fire hazards.

D. Longer Service Life Compared with Standard Cable

Traditional cables degrade rapidly under sunlight and temperature fluctuations. PV cable, however, is built to last 25+ years, aligning with the lifespan of solar panels.

E. High Flexibility for Easy Installation

Flexible Class 5 copper strands enable smooth bending and routing, reducing mechanical stress during installation in complex layouts.

F. Corrosion Resistance

Tinned copper reduces oxidation and maintains excellent conductivity even in coastal or industrial areas.

How to Choose the Right PV Solar Cable for Different Solar Projects?

Residential Rooftop Systems

For small-scale systems (3–10 kW), 4mm² or 6mm² cables are widely used because they balance current-carrying capacity and cost efficiency.

Commercial Solar Installations

Systems ranging from 50–500 kW require cables that maintain stability over longer distances. Sizes often include 6mm², 10mm², or 16mm² depending on inverter input ratings.

Utility-Scale Solar Farms

Large solar power stations operate in harsh environments and require:

-

Weatherproof XLPO insulation

-

High voltage ratings (1000V–1800V DC)

-

Larger cross-sections to reduce transmission loss

Off-Grid and Hybrid Systems

Off-grid setups typically use storage batteries, requiring PV cables capable of handling fluctuating current loads.

Selecting proper cable size improves energy yield, reduces heat generation, and extends system life.

Comparison and Application: How Does PV Solar Cable Differ from Ordinary Electrical Cable?

Durability

Ordinary cables degrade quickly under sunlight; PV cable retains integrity for over two decades.

Electrical Stability

PV cable supports high-voltage DC transmission, whereas normal household cable is optimized for lower-voltage AC.

Environmental Resistance

PV cable excels in moisture, ozone, and abrasion resistance—conditions that standard cables are not designed for.

Safety

Double-layer insulation and flame retardant construction ensure significantly higher safety levels.

How Will PV Solar Cable Evolve in the Coming Years?

Higher Voltage Cable Systems

Future solar farms will adopt higher voltage standards (1500V–1800V DC) to reduce line loss and balance-of-system cost.

Integration with Smart Monitoring

Cable temperature and conduction performance will be monitored through smart connectors and sensors to prevent failures.

Greener and More Sustainable Materials

Manufacturers will increase the use of recyclable materials and environmentally safe insulation compounds.

Enhanced Fire-Resistance Standards

International standards are adding stricter flame-retardant requirements, pushing cable technology toward safer construction.

Longer Lifespan Design

With solar plants expected to operate beyond 30 years, cable design will incorporate improved UV-blocking technologies.

PV Solar Cable Common Questions (FAQ)

Q1: How long can PV solar cable last in outdoor conditions?

A1: High-quality PV solar cable typically lasts 25 to 30 years due to XLPO/XLPE insulation, UV-resistant sheathing, and corrosion-resistant tinned copper conductors. Its lifespan matches the expected life of solar panels, ensuring consistent power output without frequent replacement.

Q2: What size of PV solar cable should be used for a residential solar system?

A2: Most residential systems use 4mm² or 6mm² cables depending on inverter requirements, panel current, and cable length. Larger cross-section sizes are needed when cable runs exceed 30 meters or when current output approaches rated limits.

How Does PV Solar Cable Support the Future of Renewable Energy?

PV solar cable plays a crucial role in optimizing the efficiency, safety, and longevity of photovoltaic systems. Its combination of high conductivity, weather resistance, flame retardancy, and long service life ensures stable energy output in all environmental conditions. As the solar industry advances, PV cable technology will continue to evolve toward higher voltage capabilities, enhanced sustainability, and smarter monitoring integration.

Manufacturers like DAYA provide PV solar cables engineered for long-term performance in residential, commercial, and utility-level installations. Their quality-focused design ensures reliable power transmission and reduced maintenance over the lifetime of solar projects.

For detailed product specifications, customized cable solutions, or project-based technical support, contact us to receive professional guidance tailored to your solar installation needs.