How Does a LiFePO4 Battery Deliver High-Cycle Stability and Long-Term Performance?

2025-12-11

A LiFePO4 battery, also known as a lithium iron phosphate battery, is a rechargeable lithium-ion energy storage system engineered for environments that demand long service life, thermal stability, and predictable performance across extensive charge–discharge cycles. Its cathode material (lithium iron phosphate) provides strong structural integrity, enabling superior safety and consistent voltage regulation.

Below is a summary of representative LiFePO4 battery parameters presented in a single structured table:

| Parameter Category | Typical Specification Range |

|---|---|

| Nominal Voltage | 12.8V / 24V / 48V / custom high-voltage configurations |

| Capacity Options | 50Ah–500Ah modules; scalable energy packs |

| Cycle Life | 3,000–10,000 cycles depending on C-rate and thermal management |

| Operating Temperature | -20°C to 60°C discharge / 0°C to 45°C charge |

| Charge Method | CC/CV with recommended charge voltage 14.4V–14.6V (12V module equivalent) |

| Discharge Rate | Continuous 1C; peak 2C–3C depending on BMS configuration |

| Safety Features | Overcharge, over-discharge, short-circuit, temperature, cell balancing |

| Energy Density | 90–160 Wh/kg depending on cell structure |

| Form Factors | Prismatic, cylindrical, rack-mounted, wall-mounted, containerized |

How Does a LiFePO4 Battery Maintain Stability Under High-Cycle Stress?

LiFePO4 chemistry delivers its long cycle life due to the strong P-O bond within the phosphate framework, preventing structural collapse during lithium extraction and insertion. Unlike chemistries with layered oxide structures, LiFePO4 exhibits exceptional thermal resistance and low risk of oxygen release, dramatically reducing thermal runaway scenarios.

High-cycle stability is further supported by advanced battery management systems that monitor real-time voltage dispersion, cell temperature gradients, and discharge symmetry. These mechanisms ensure that each cell operates within a specified threshold, mitigating degradation factors such as lithium plating or unbalanced parallel paths.

Thermal distribution also contributes to performance stability. LiFePO4 cells dissipate heat more uniformly, reducing localized hot spots that typically accelerate degradation in other chemistries. The lower internal resistance of mature LiFePO4 designs enables high output efficiency, maximizing usable energy while optimizing power delivery during sustained load consumption.

How Does a LiFePO4 Battery Compare to Other Energy Storage Chemistries in Real-World Applications?

When evaluating lithium iron phosphate relative to other lithium-ion chemistries—especially nickel-manganese-cobalt systems—several operational distinctions emerge. The voltage profile of LiFePO4 is more stable near its nominal voltage, which ensures predictable power transfer in distributed energy applications such as residential solar storage or microgrid buffering. In contrast, high-energy chemistries may exhibit energy density advantages but often require stricter thermal control and entail shorter cycle durability.

In transportation or off-grid systems, the difference becomes even more apparent. LiFePO4 batteries demonstrate consistent energy output across wide temperature ranges, an advantage when devices operate in outdoor, remote, or industrial environments. Additionally, maintenance cycles are generally reduced due to lower degradation rates, allowing predictable cost-of-ownership modelling over multi-year operational windows.

In commercial equipment—such as forklifts, AGVs, and portable power stations—the inherent safety profile of LiFePO4 adds an operational advantage. It enables tightly stacked module designs and allows high-current draw without imposing disproportionate heat buildup. Meanwhile, the long service life reduces frequency of pack replacement, enhancing ROI for systems with continuous daily cycles.

How Are LiFePO4 Batteries Shaping Future Trends in Residential, Industrial, and Utility-Scale Energy Storage?

The advancement of LiFePO4 battery technology plays a critical role in decentralized energy storage architecture. As demand for renewable integration rises, microgrids and residential solar storage systems increasingly rely on lithium iron phosphate due to its predictable cycle life and compatibility with bidirectional inverters. This enables households and commercial sites to maximize self-consumption and reduce dependence on grid-supplied peak power.

Utility-scale deployments are also shifting toward LFP-based racks and containerized systems. The chemistry’s safety characteristics allow for denser installations without extensive cooling systems, improving land-use efficiency in battery farms. The capability to withstand thousands of high-depth cycles positions LiFePO4 as a viable solution for grid balancing, frequency regulation, and peak-shaving services.

Industrial automation further accelerates adoption. Autonomous robots, warehouse vehicles, and remote power stations benefit from rapid charging, high discharge stability, and long operational windows. The consistency of LiFePO4 across extreme environments makes it suitable for maritime systems, telecom infrastructure, and heavy-duty transport electrification.

Design evolution also supports emerging trends. Higher-capacity prismatic cells, advanced BMS algorithms, and integrated smart-monitoring platforms enhance pack-level intelligence. These features enable predictive maintenance and remote diagnostics, further reducing downtime in critical systems.

How Can System Designers Optimize LiFePO4 Battery Deployment for Maximum Reliability?

System design for LiFePO4 energy storage requires balancing charge parameters, load profiles, thermal management, and BMS coordination. Charging should follow a constant-current, constant-voltage method aligned with the manufacturer’s recommended limits. In high-demand industrial scenarios, maintaining charge currents below 0.5C can significantly extend cycle life.

Thermal strategy is equally important. Although LiFePO4 cells tolerate heat well, consistent ambient control between 15°C and 30°C maximizes longevity. For rack or containerized installations, air circulation pathways must prevent clusters of elevated temperatures. In mobile power applications, metal enclosures with passive ventilation or active cooling offer further protection.

Parallel-series configuration planning is central to ensuring voltage uniformity. Pre-balancing individual modules before integration minimizes initial cell imbalance. When scaling systems, selecting a BMS capable of real-time balancing and multi-string synchronization ensures longevity and stable performance under fluctuating load cycles.

Additionally, protective circuitry should address over-voltage tolerance, current spikes during motor start-up, and transient surges from inverters. The recommended discharge cut-off voltage (e.g., 10.0V for a 12.8V pack) must be consistently enforced to prevent irreversible capacity loss.

Common Questions About LiFePO4 Batteries

Q: How long does a typical LiFePO4 battery last in daily cycling environments?

A: A well-designed LiFePO4 battery pack generally delivers between 3,000 and 10,000 cycles depending on discharge depth, operational temperature, and charging current. Systems maintained under moderate temperatures and conservative C-rates experience substantially extended life, often exceeding ten years of regular use.

Q: What is the recommended storage procedure for LiFePO4 batteries during long periods of inactivity?

A: Stored batteries should be maintained at approximately 50% state of charge and placed in an environment between 10°C and 25°C. Periodic inspection every three to six months is advised to ensure voltage stability. Packs should not be stored in a fully discharged state, as this may lead to undervoltage conditions affecting long-term recoverability.

The LiFePO4 battery stands as a highly stable and long-lasting energy storage solution suited for residential, industrial, commercial, and utility-grade applications. Its structural integrity, thermal stability, and deep-cycle resilience contribute to dependable performance across demanding environments. As the energy storage sector expands, this chemistry is positioned to remain a central component of microgrids, transport systems, renewable integration, and autonomous infrastructure.

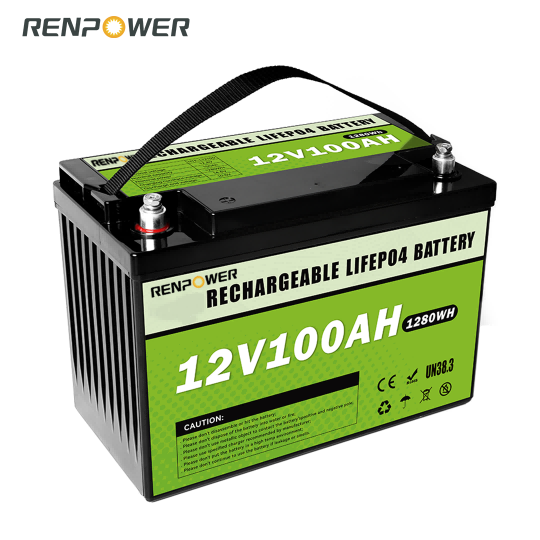

For organizations seeking dependable LiFePO4 energy solutions, Ningbo Renpower Technology CO., LTD provides engineered products tailored to diverse application scenarios. The company supports technical customization, cycle-life optimization, and long-term deployment planning for global clients across multiple industries. For detailed specifications or procurement inquiries, contact us for further consultation and project support.