How Do You Choose the Right Distribution Box for Your Project?

2025-07-25

For electrical contractors, engineers, or facility managers, distribution boxes are more than just utility equipment — they're foundational elements that impact safety, scalability, and system performance.

What Makes a Good Distribution Box?

A quality distribution box ensures:

Reliable load distribution

Safe circuit protection

Ease of maintenance and future upgrades

Compliance with local electrical codes

Whether you're working on a residential, commercial, or industrial project, choosing the right box starts with understanding the site’s load requirements and application demands.

Key Considerations When Selecting a Distribution Box

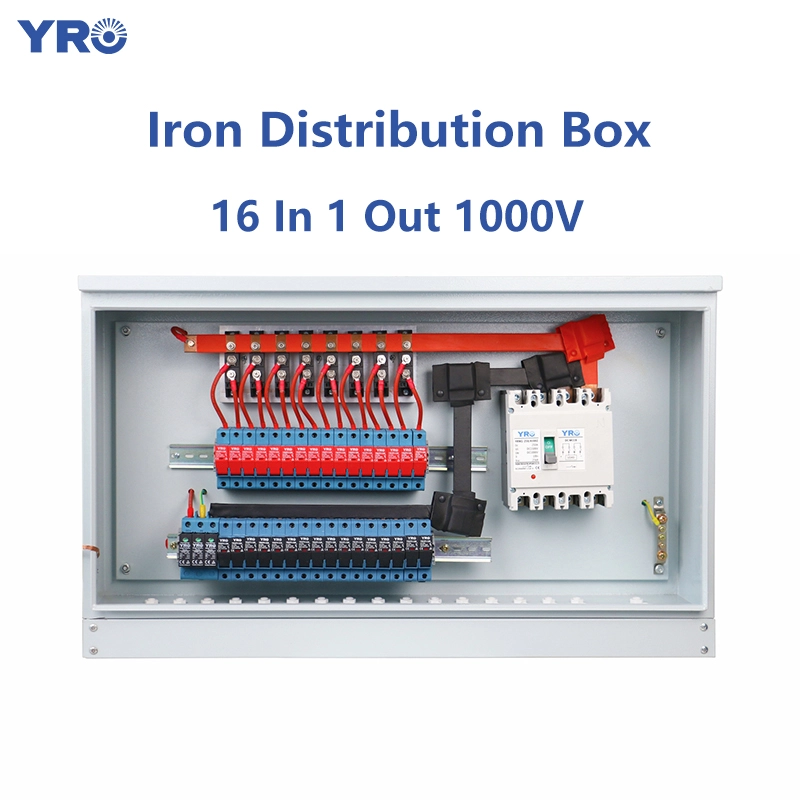

1. Material

Plastic (polycarbonate/ABS): Lightweight, corrosion-resistant — ideal for indoor, low-risk environments.

Metal (steel/stainless): Durable, fire-resistant — suited for outdoor or industrial applications.

2. Ingress Protection (IP Rating)

For outdoor or dusty environments, look for IP65 or higher to ensure protection against water and particles.

3. Busbar Design and Phase Configuration

Properly rated busbars (single, double, three-phase) can improve performance and safety. Choose based on load and supply type.

4. Customization and Modularity

In large projects, opt for boxes that support modular expansion, DIN rail compatibility, and easy breaker configuration.

5. Safety Compliance

Ensure the box complies with standards like IEC 61439, UL 508A, or local regulatory codes.

Installation Tips

Allow for ventilation to reduce overheating.

Label circuits clearly for future serviceability.

Always provide adequate space for wire bending and future upgrades.

A distribution box may seem like a small component in a larger electrical ecosystem, but the right choice can simplify installation, improve safety, and reduce long-term maintenance. It’s not just a box — it’s the backbone of your electrical infrastructure.