How Do Underwater Lamp Aluminum PCBs Enhance Reliability in Submerged Lighting Systems?

2025-12-11

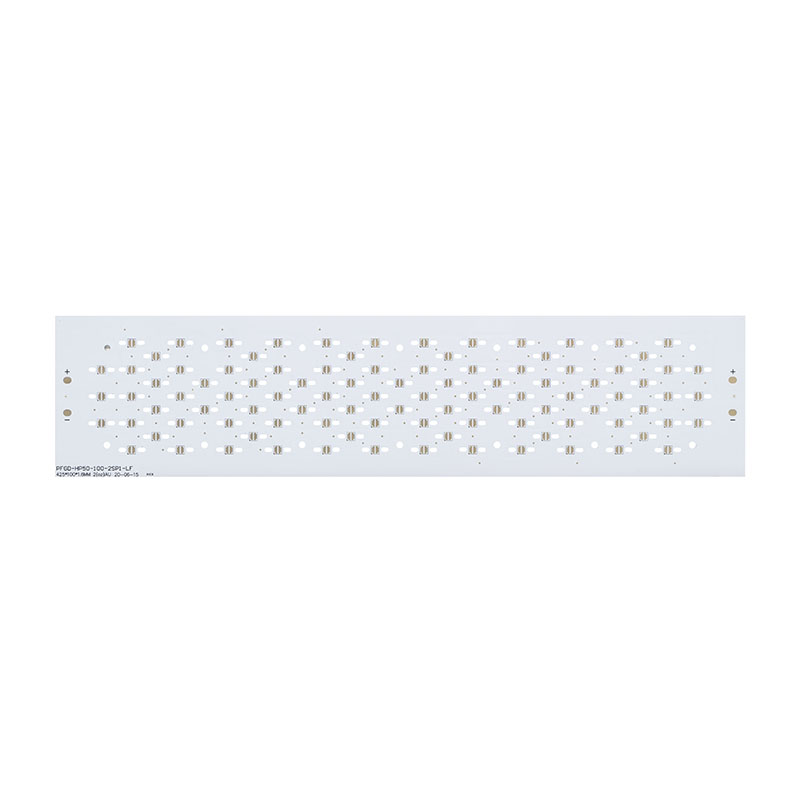

Underwater lighting solutions rely on material stability, thermal control, and long-term corrosion resistance to perform under continuous exposure to moisture, pressure, and fluctuating temperatures. Underwater Lamp Aluminum PCBs are engineered specifically for such demanding environments, integrating enhanced heat dissipation structures, moisture-resistant surface treatments, and mechanical durability that allows LED modules to operate safely and efficiently.

The central focus is to explain how structural design, materials science, and thermal engineering converge to ensure underwater lighting systems remain stable even during extended operation with high lumen output. Key parameters, from copper trace thickness to dielectric insulation strength, significantly influence the electrical and thermal balance needed for maintaining LED package integrity. These parameters are therefore detailed below in a professional, engineering-driven format.

Technical Specification Overview of Underwater Lamp Aluminum PCB

| Parameter Category | Specification Range | Technical Impact |

|---|---|---|

| Base Material | Aluminum alloy 5052/6061/3003 | Provides corrosion resistance, structural rigidity, and improved thermal transfer. |

| Copper Thickness | 1 oz – 4 oz | Influences current-carrying capacity, thermal distribution, and electrical reliability. |

| Dielectric Layer | 50 μm – 150 μm high-thermal-conductivity insulator | Determines voltage isolation, thermal impedance, and breakdown resistance in submerged conditions. |

| Thermal Conductivity | 1.0 W/m·K – 5.0 W/m·K | Directly affects LED junction temperature stability. |

| Surface Finish | ENIG, Immersion Tin, OSP | Enhances solderability and corrosion resistance against moisture exposure. |

| Solder Mask | Waterproof, UV-resistant, high-adhesion coating | Protects circuits from water, chemicals, and abrasion. |

| Mechanical Properties | Warpage ≤ 0.75%, flex tolerance defined by alloy type | Ensures PCB remains physically stable under pressure changes. |

| Voltage Withstand Capacity | 1500–4500 V | Ensures electrical safety under submerged operation. |

| Operating Temperature | -40°C to +130°C | Suitable for cold environments and high-temperature LED operation. |

| LED Compatibility | High-power LED packages 1W–10W | Supports high-brightness underwater illumination. |

These specifications form the engineering baseline of the product category, helping designers identify suitability for individual underwater luminaire architectures such as spotlight modules, surface-mounted illuminators, RGB pool lights, and wide-area underwater flood lamps.

Structural Engineering and Thermal Dynamics of Underwater Lamp Aluminum PCBs

The performance of underwater lighting systems is strongly influenced by the capability of the PCB substrate to disperse heat and resist environmental stress. The aluminum core serves not only as a heat sink but also as a structural backbone that resists deformation due to water pressure, hydraulic shock, or long-term mechanical stress caused by thermal cycling.

The dielectric layer built between the copper circuit and aluminum core is critical for both insulation and thermal transfer. High thermal conductivity dielectrics reduce the junction temperature of LEDs, which can otherwise degrade lumen maintenance and induce color shift. Illumination installed in confined aquatic spaces such as pool niches or fountain housings often experiences insufficient natural convection, making PCB thermal efficiency a decisive factor.

In addition, underwater environments introduce electrochemical risks. Poor protective finishes may result in galvanic corrosion, ultimately compromising conductivity. High-grade surface finishes such as ENIG (Electroless Nickel Immersion Gold) provide a barrier layer that preserves solderability while resisting oxidation and moisture intrusion. LED underwater lamps designed with high-conductivity aluminum PCBs demonstrate lower operating temperatures, longer LED lifetimes, reduced failure rates, and improved color stability.

Designers must evaluate the correlation between copper weight and thermal path efficiency. Heavier copper layers allow more uniform heat distribution but require more precise manufacturing controls to prevent delamination or over-etching. With the increasing global deployment of RGB color-changing underwater fixtures, which often require high peak current, choosing the proper copper thickness becomes essential for maintaining electrical reliability.

Application Scenarios and Reliability Considerations in Submerged Environments

Underwater Lamp Aluminum PCBs are applied across a range of water-based installation types, each presenting unique stress conditions. In swimming pools, for example, chemicals such as chlorine can accelerate metal corrosion, requiring coatings that resist chemical permeation. In ocean-based installations, saltwater’s corrosive properties demand superior surface treatment and seal integrity. Fountains and aquascapes often involve rapid temperature fluctuations and constant water movement, which require substrate rigidity and bonding strength between the dielectric and aluminum base.

The mechanical design of underwater lamps typically includes thermal interface materials, LED modules, driver compartments, and waterproof housings. Aluminum PCBs must therefore support long-term adhesion of solder joints, withstand repeated heating cycles, and maintain dimensional accuracy. Furthermore, underwater lamps frequently operate for long durations without rest, intensifying thermal load. Systems designed with inadequate thermal management show increased chip defects, discoloration, and moisture-related failures.

For advanced lighting control systems—such as smart underwater RGB lamps equipped with DMX or wireless interfaces—stable PCB architecture ensures signal integrity and reduces the risk of micro-crack formation in copper traces. Aluminum substrates prove particularly advantageous in these contexts because they reduce thermal hotspots that could otherwise affect decoder IC performance.

The reliability curve of underwater lamps is also shaped by ingress protection (IP) levels. A durable aluminum PCB with a controlled dielectric thickness can support higher IP ratings by offering additional internal structural stability. This allows the lamp to maintain consistent illumination even in deep or high-pressure installations.

Future Trends Influencing Underwater Lamp Aluminum PCB Development

Several technological and industry trends are shaping the evolution of Underwater Lamp Aluminum PCBs:

1. Higher Thermal Conductivity Materials

Manufacturers are gradually moving toward dielectrics with thermal conductivities exceeding 3.0 W/m·K, enabling next-generation high-power underwater LEDs. These materials help maintain luminous efficiency while reducing stress on LED chips.

2. Integration with Smart Control Systems

The growing demand for underwater RGB and tunable-white systems increases the need for PCBs capable of supporting multi-channel control logic and higher current densities. Aluminum substrates with optimized copper design support stable high-frequency performance.

3. Thinner PCB Structures

To achieve lighter lamp modules and improve LED-to-water thermal transfer, there is growing interest in thin-core aluminum PCBs. These minimize thermal impedance while preserving mechanical strength.

4. Enhanced Environmental Coatings

Future underwater LED systems will likely adopt specialized anti-salt, anti-chlorine, and anti-biofouling coatings. These protective solutions aim to extend operational lifetimes in harsh oceanic or chemically treated aquatic environments.

5. Sustainability and Thermal Efficiency Regulations

As environmental standards evolve, underwater lighting solutions are expected to adopt materials and designs that reduce energy consumption, increase recyclability, and enhance LED system longevity. Aluminum PCBs, being recyclable and thermally efficient, fit well within these future regulatory landscapes.

Frequently Asked Questions About Underwater Lamp Aluminum PCBs

Q1: How does aluminum PCB construction improve underwater lighting performance compared to standard FR4 PCBs?

A1: Aluminum PCBs significantly outperform FR4 in thermal conductivity, offering heat transfer rates that reduce LED junction temperature and minimize thermal stress. FR4 substrates tend to trap heat, which accelerates LED decomposition and color drift. Aluminum PCBs distribute heat quickly through their metal core, allowing the lighting fixture to maintain stable illumination even in enclosed underwater housings with restricted airflow. Additionally, aluminum substrates provide improved mechanical strength, corrosion durability, and dimensional stability, which are crucial for submerged applications.

Q2: What factors determine the long-term durability of an underwater lamp aluminum PCB?

A2: Durability depends on several integrated factors: alloy grade, dielectric thermal performance, copper trace thickness, protective finishes, solder mask adhesion, and moisture resistance. The interaction between these elements influences how well the board resists delamination, thermal cycling fatigue, electrochemical corrosion, and mechanical deformation. High-performance waterproof coatings and stable thermal interfaces further ensure that LED modules remain operational for many years even under continuous underwater exposure. Reliability also improves when manufacturers maintain precise control over dielectric thickness to ensure consistent thermal impedance and voltage isolation.

Professional-Grade Underwater Lighting Performance Built on Advanced PCB Architecture

A high-quality Underwater Lamp Aluminum PCB functions as the foundation of modern submerged lighting systems, determining not only thermal stability but also electrical precision, mechanical resilience, and long-term reliability. Its engineered structure supports high-power LEDs, advanced control architectures, and demanding environmental conditions across pools, fountains, marine installations, and decorative water landscapes. As underwater lighting continues to evolve toward higher power densities, intelligent control systems, and more stringent lifespan expectations, aluminum PCBs will remain essential for achieving thermal efficiency and structural integrity.

For organizations seeking dependable underwater lighting solutions, choosing products manufactured with rigorous substrate standards and advanced material technologies is critical. Huaerkang continues to develop underwater lamp aluminum PCB solutions that emphasize heat management, corrosion resistance, mechanical durability, and long-term operational stability.

For project consultation, technical specifications, or OEM cooperation, contact us to explore tailored underwater PCB solutions that align with your performance objectives.