How Are Plastic Enclosures Applied Across Industrial and Commercial Environments?

2025-12-29

Abstract

Plastic Enclosures are widely used protective housings designed to safeguard electrical, electronic, and control components from environmental, mechanical, and operational risks. This article provides a structured and technically grounded overview of how plastic enclosures function, how their parameters influence real-world applications, and how they are selected for diverse industries. The discussion focuses on design logic, material properties, protection standards, and practical deployment scenarios, supported by detailed specifications and commonly asked technical questions. The objective is to offer a clear reference framework for engineers, integrators, and procurement specialists seeking reliable enclosure solutions.

Table of Contents

- 1. How Do Plastic Enclosures Serve Industrial Protection Needs?

- 2. How Are Plastic Enclosure Parameters Defined and Evaluated?

- 3. How Are Plastic Enclosures Selected for Specific Applications?

- 4. How Do Plastic Enclosures Address Common Technical Questions?

1. How Do Plastic Enclosures Serve Industrial Protection Needs?

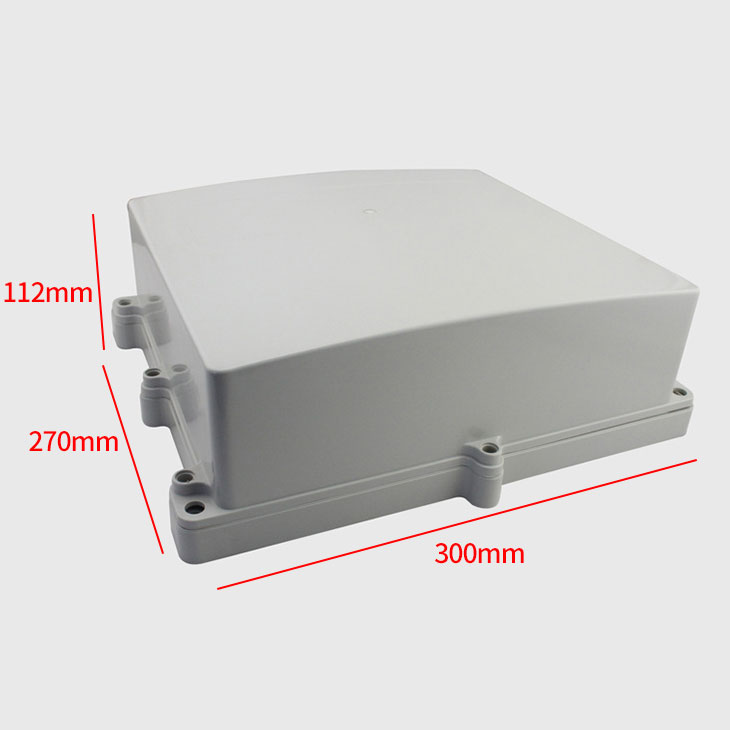

A Plastic Enclosure is a non-metallic housing engineered to protect internal components such as circuit boards, terminals, relays, sensors, and communication modules. These enclosures are commonly manufactured from thermoplastic materials and are designed to isolate sensitive equipment from dust, moisture, chemicals, vibration, and accidental contact.

In industrial and commercial environments, plastic enclosures are frequently deployed in automation systems, power distribution panels, renewable energy installations, telecommunications cabinets, and outdoor control units. Their non-conductive nature reduces electrical risk, while their corrosion resistance enables long-term operation in humid or chemically aggressive conditions.

From a system-level perspective, the enclosure acts as a physical interface between internal electronics and external operating conditions. Proper enclosure selection directly affects system reliability, maintenance cycles, and compliance with international safety standards.

2. How Are Plastic Enclosure Parameters Defined and Evaluated?

Technical parameters define the performance boundaries of a plastic enclosure. These parameters are evaluated during design and procurement to ensure suitability for the intended operating environment.

Key Product Parameters Overview

| Parameter | Specification Range | Technical Significance |

|---|---|---|

| Material Type | ABS, Polycarbonate (PC), PC+ABS | Determines impact resistance, temperature tolerance, and UV stability |

| Ingress Protection | IP54 to IP67 | Indicates resistance to dust and water penetration |

| Operating Temperature | -40°C to +120°C | Defines environmental adaptability |

| Flame Rating | UL94 HB / V-0 | Measures fire resistance performance |

| Mechanical Strength | IK07–IK10 | Evaluates resistance to external impact |

| Mounting Options | Wall, Pole, DIN Rail | Supports installation flexibility |

Material selection plays a critical role. ABS enclosures are commonly used in indoor applications due to balanced strength and cost efficiency. Polycarbonate enclosures are preferred for outdoor or high-impact environments because of superior toughness and UV resistance.

Ingress protection ratings define how well an enclosure resists environmental intrusion. Higher IP ratings are typically specified for outdoor, washdown, or coastal installations where water exposure is frequent.

3. How Are Plastic Enclosures Selected for Specific Applications?

Selecting a plastic enclosure involves matching application conditions with enclosure capabilities. Environmental exposure, internal heat generation, access frequency, and compliance requirements are evaluated as part of the selection process.

For automation control systems, enclosures must support precise cable management, internal mounting bosses, and adequate airflow or thermal dissipation. In renewable energy systems, enclosures often require UV-stabilized materials and higher sealing performance to withstand prolonged outdoor exposure.

In telecommunications and data acquisition installations, plastic enclosures are chosen for their electromagnetic neutrality and lightweight structure, which simplifies pole or wall mounting. For chemical processing environments, material resistance to oils, solvents, and cleaning agents becomes a determining factor.

Standardization also influences selection. Compliance with IEC, UL, and NEMA standards ensures that enclosures can be deployed across global markets without redesign or requalification.

4. How Do Plastic Enclosures Address Common Technical Questions?

How does a plastic enclosure perform compared to a metal enclosure?

Plastic enclosures provide electrical insulation, corrosion resistance, and reduced weight, while metal enclosures offer higher shielding against electromagnetic interference. Application conditions determine the appropriate choice.

How is heat managed inside a plastic enclosure?

Heat dissipation is managed through material thermal properties, enclosure geometry, ventilation accessories, and optional heat sinks or fans when required.

How long can a plastic enclosure operate outdoors?

With UV-stabilized materials and appropriate IP ratings, plastic enclosures can maintain structural integrity and sealing performance for many years in outdoor environments.

How are custom modifications implemented?

Custom cutouts, inserts, and mounting features are typically integrated through CNC machining, injection mold design adjustments, or secondary processing to meet specific system requirements.

Conclusion

Plastic Enclosures play a foundational role in modern electrical and electronic system protection. Through appropriate material selection, parameter evaluation, and standards compliance, these enclosures enable reliable system operation across a wide range of industrial and commercial applications.

As manufacturing technologies and material science continue to evolve, enclosure design is becoming more adaptable, precise, and application-oriented. Reliable suppliers with engineering expertise are essential to ensuring long-term performance and compatibility.

Ruidafeng provides professionally engineered plastic enclosure solutions designed to meet international standards and diverse application requirements. For tailored specifications, technical consultation, or project-based solutions, contact us to discuss how appropriate enclosure design can support system reliability and operational efficiency.